DPL Series Multi-Purpose Fluid Bed Processor, Fluid Bed Dryer

This equipment is set with top spray, bottom spray, and tangent spray functions in order to carry out drying, granulation, coating and pelletizing processes. And this equipment absolutely comply with the requirements of GMP.

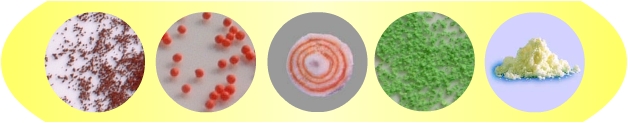

Finished products:

equipment

Application

This equipment is set with top spray, bottom spray, and tangent spray functions in order to carry out drying, granulation, coating and pelletizing processes. And this equipment absolutely comply with the requirements of GMP.

This equipment is designed and manufactured on the basis of absorption and digestion the similar products in foreign country.

Features

1. This equipment integrate mixing, granulating, and drying in one unit, and able to record and print multi-group operation

process parameters through PLC and HMI control.

2. High drying efficient, uniform particles

3. Inlet AHU consists of 3 grade filter, including primary filter(G4), medium efficiency filter(F8), HEPA filter(H11-H13).

4. Equipped with cold and hot air throttle, with high precision temperature control, and using PID automatic control

5. The exhaust dust collection filter is optionally designed for protected environment.

6. Lifter unloaded or vacuum unloading is designed and offered to form the dust free unloading from

DPL fluid bed system in order to meet the requirements of current GMP regulation.

7. Anti-explosion as option, the 2 bar, 10 bar and 12 bar powder explosion proof design is selectable.

8. Dehumidification system and WIP online cleaning system are optional.

Main Technical Parameters

| Items | Unit | DPL5 | DPL10 | DPL20 | DPL30 | DPL60 | DPL120 | DPL200 | DPL300 | |

| Materials Bowl Volume | Top spray | L | 22 | 45 | 55 | 100 | 220 | 460 | 670 | 1000 |

| Bottom Spray | 13 | 25 | 32 | 75 | 100 | 180 | 380 | 860 | ||

| Tangent Spray | 10 | 15 | 28 | 50 | 80 | 120 | 180 | -- | ||

| Production Capacity : | Top Spray | Kg/batch | 5 | 10 | 20 | 30 | 60 | 120 | 200 | 300 |

| Bottom Spray | 5 | 10 | 20 | 30 | 40 | 60 | 150 | 200 | ||

| Tangent Spray | 5 | 10 | 15 | 25 | 40 | 60 | 100 | -- | ||

| Steam | Pressure | Mpa | 0.4-0.6 | |||||||

| Consumption | Kg/h | 30 | 30 | 65 | 75 | 150 | 200 | 290 | 460 | |

| Compressed air | Pressure | Mpa | 0.4-0.7 | |||||||

| Consumption | M3/min | 0.8 | 0.8 | 1 | 1 | 1.5 | 2 | 3.5 | 3.5 | |

| Fan power | kw | 5.5 | 5.5 | 7.5 | 15 | 22 | 30 | 37 | 55 | |

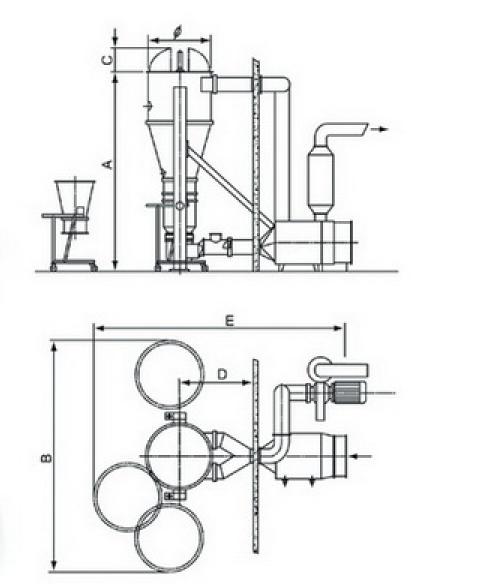

| Overall Dimension | B | mm | 1200 | 1200 | 1450 | 1450 | 2680 | 2800 | 3200 | 4200 |

| E | mm | 2550 | 2850 | 3250 | 3250 | 3750 | 3750 | 4600 | 4850 | |

| A | mm | 2800 | 2800 | 3000 | 3000 | 3230 | 4250 | 4960 | 5450 | |

| Φ | mm | 550 | 600 | 600 | 750 | 1000 | 1200 | 1400 | 1600 | |

Layout Drawing